DR Graphics is a independent manufacturer and supplier with a total solution for your (inplant) ink mixing kitchen/laboratory.

Our product range contains the following products:

- Inkdispensing systems for Offset (conventional and/or UV) inks

- Ink weighing scales (basic version)

- Advanced weighing scales linked to a Touch panel pc with formulation software evt. in combination with a photospectro meter

- inkmixers & inkshakers

- ink-proofing (testing) equipment

- Vacumatic® sealingmachine for Vac-pack cans

- Crimpingtools for Vac-pack cans.

These components are listed into several documents, below we explain the Spot Color Master® and equipment options that are currently available.

The Spot Color Master

The Spot Color Master® is a complete new ink dispensing system which especially is designed for packaging printers how will reproduce their (spot)mixing (PMS/HKS) colors in a easy way.

Whether you currently manually mix your spot colors or you buy ready made mixes from you ink supplier, you will benefit from using a professional Spot Color Master® Ink Lab.

You will significantly improve the efficiency, accuracy and consistency of your mixing colours.

It will also save you cost, time and waste.

The Spot Color Master® is ergonomically and safely designed (Two-hand control) inkdispenser.

All activities done by the operator (control of the Touch panel pc, dispensing of ink and tin exchange) are from a central position at the inkdispenser.

The weighing platform (where we put the empty can) is also adjustable in height.

Touch panel

The Touch panel pc is linked to a weighing scale on which we put the empty ink can/container.

With the software the operator can choose his color and the quantity he wants to prepare.

The operator has the option to choose his color by input (name or number) or swipe through the list.

Then the Touch panel pc will show the operator the steps to follow to get his accurate mix.

A color bar will help the operator for the status of the mix.

On the Touch panel it selves the operator can add, remove and change recipes.

The more advanced “Colorpack” software is further expanded with a management information system like stock control, job reports, traceable batch number, materials in/out etc.

Also the “Colorpack” software can be linked to Networking and Remote access.

The Spot Color Master® is in the basic version appropriate for 16 base colors (conventional ink)

of 2,5 kg Vac-pack cans (vacuum can) which are supplied by the various ink manufacturers.

Upon request other versions are available:

- UV ink in metal or plastic can (Vac-pack or cylindrical)

- Conventional and/or UV ink in cylindrical can

- Other ink container

These 16 Base colors are segmented over 8 dispensing sections, each section contains 2 Base colors. With the 2-way dispensing nozzle the printer has the opportunity to dispense exactly the quantity he needs.

A firm press will make large doses possible in a short period of time and for high precision small doses ( 0.1 gram), a light press of the dosing-lever will release a fine spurt of ink.

After making a new color the printer doesn’t have to reseal the lids of the base colors, the can is always sealed with a follower press plate which prevents air and dirt getting into the ink.

Cleaning of the dosing valves takes just seconds after the production of your spot color and in a simple way a empty ink can (base color) will be replaced.

Maintenance is kept to a minimum thanks to the extremely sophisticated construction and the use of sustainable materials (stainless steel and Alumnium).

The Spot Color Master® is low cost in comparison with other systems.

It is a simple “Easy” to use manual device which are controlled by pneumatic components.

The Spot Color Master® works only with compressed air and can be positioned on a 1½ square meter.

Electrical power is only needed for the scale (optional with Touch panel pc) which can be adjusted in height (flexible plateau for the weighing scale).

Benefits

- Money saver – No skin build up, efficient use of ink and using more of the ink from the tin all meanless ink waste

- Time saver – Quick and Easy to use

- Exact dosing – From 0.1 gram

- Environment – The Spot Color Master® promotes a better, cleaner environment

- Efficient – Fast production of nearly all spot colors on any time

- Low maintenance – Quick and Easy to clean (less need of solvents)

- Investment – Low cost in comparison with other systems

- Return On investment – Low cost of the equipment, reduced cost to makespot colors, and less ink waste equals a much faster”Return On Investment”

- Power – Works only with compressed air

Technical data

-

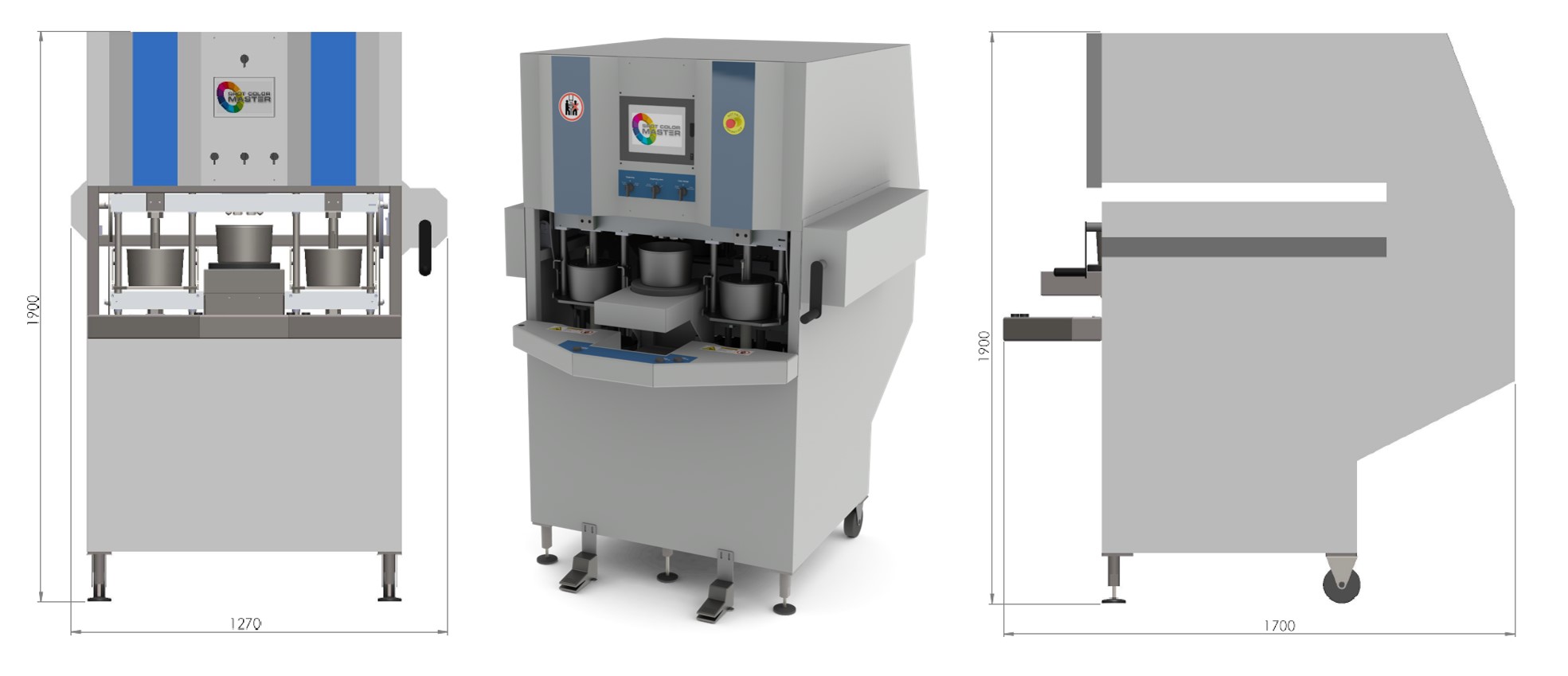

- Dimensions: 1700 x 1270 x 1900mm (L x W x H)

- Pressure: Max. 8 Bar / 116 PSI

- Power adaptor: Input 100-240VAC – 50/60Hz -1,5A

- Output to Touch panel & Scale: 12Volts – 5,0A

- Base color ink can/container size: Vac-pack (vacuum) can 2,5 kg (other sizes on request)

- Color: RAL 7035/5007

The Spot Color Master® is developed in collaboration with the University of Twente (Industrial Product Development) and aims;

- Lower purchase costs of Base colors instead of ready mixed inks

- Lower stock

- Less ink consumption

- Less Labor costs

- Less ink waste (no dirty ink can or skin building on the ink)

- Less transportcosts

- Standardization

- Efficiency

Voor meer informatie kunt u ons bellen op +31 (0) 572 39 29 15 of het CONTACTFORMULIER invullen: